Which is better, COB or GOB?

COB LED DISPLAY VS GOB COB LED DISPLAY VS GOB: Most people may be more familiar with COB LED displays, but they may not know The most up-to-date pixel protection technology called GOB LED display. In this news, we will discuss how GOB or Glue on Board can help protect LED displays.

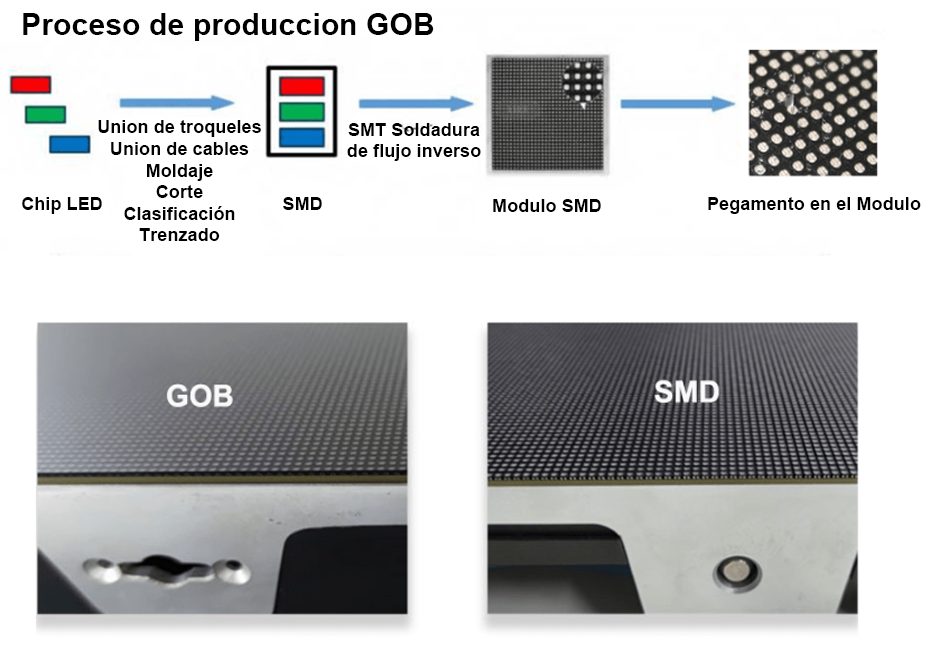

What is the GOB? Glue on Board is abbreviated as GOB. It is an epoxy resin that is applied to the surface of the display modules, to create an overall layer of glue that improves the sealing of SMD displays. It is a technology developed for the topic of protection of LED screens. GOB LED display can work in any challenging environment, which makes it resistant to water, dust, shocks and UV rays; It is widely used in restaurants, hotels, bars and stadiums.

GOB LED display technology It can be applied in various ways to protect LED displays from damage and reduce maintenance costs. This technology is especially useful for rental LED screens, which move frequently and require a high level of protection. such as small pitch GOB LED displays, GOB flexible LED displays, GOB rental LED displays, GOB floor LED displays and irregular shaped GOB LED displays. They can provide waterproof, shockproof and dustproof protection to ensure these LED displays remain in good condition.

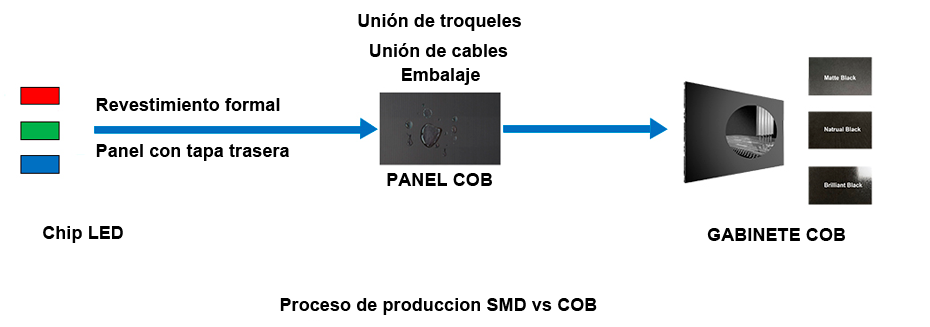

However, GOB is not a breakthrough in packaging technology, but rather an improvement on the existing SMD surface mount process, which essentially still belongs to the family. SMD. We would prefer to call it GOM “Glue On Module”.

COB vs GOB

GOB has most of the characteristics of SMD.

1. COB LED display offers an incredibly high color contrast ratio of 10.000:1, much higher than the 5.000:1 contrast ratio of normal black SMD LED. GOB can increase the contrast ratio of SMD up to 100000:1

2. COB LED modules have a water and moisture resistance rating of IP65 on the front and IP30 on the rear, which allows them to be used even in extreme conditions such as ice water or boiling water at 100 degrees, thus providing perfect protection in humid and cold regions, such as Russia.

3. The optical design features high fill factor and small pixel factor, “surface light source” emission, matte coating, high contrast, reduced glare and effective blue light resistance, which can effectively reduce the appearance of moiré. Is especially Suitable for high-end applications, such as studios, weather forecast rooms, traffic rooms, satellite command centers and broadcast centers.

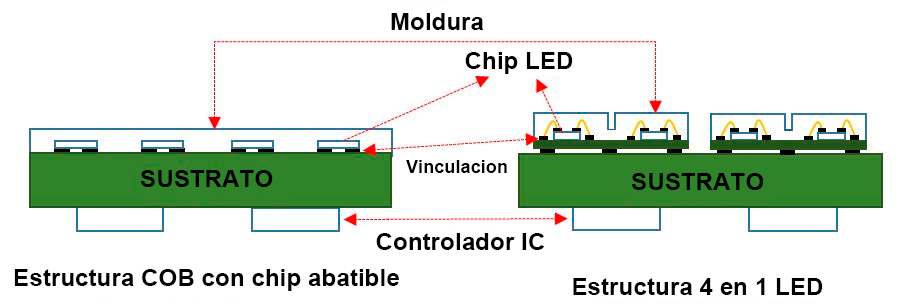

4. The COB LED module has an epoxy resin coating on its surface. Because the pixel size is small, the components are sealed to the PCB, preventing them from being exposed. This makes the LED display resistant to collision damage and drops, as well as being dust, water, moisture and UV proof.

5. Packaging technology COB has a small pixel density, allowing for an ultra-wide viewing angle of 180°. Light losses due to refraction are minimal, allowing you to enjoy the same viewing angle from any position in front of the center of the screen, which Ensures color consistency and brightness no matter the angle.

SMD modules require reflow soldering, which, when the solder paste reaches a temperature of 240 °C, causes an 80% weight loss of the epoxy resin, causing the glue to easily separate from the cup. LED. In contrast, COB technology does not require reflow soldering and is therefore more stable. Additionally, solder paste does not need to go through ROHS approval.